A truck repair shop will get your rig back on the road, where it belongs. From regular maintenance like oil changes and tire rotations to handling engine diagnostics and major repairs, these shops are equipped to manage a wide range of truck issues.

We provide trustworthy, durable solutions tailored specifically to your truck. Whether you own a light-duty private pickup or a heavy-duty commercial vehicle, we want you onboard!

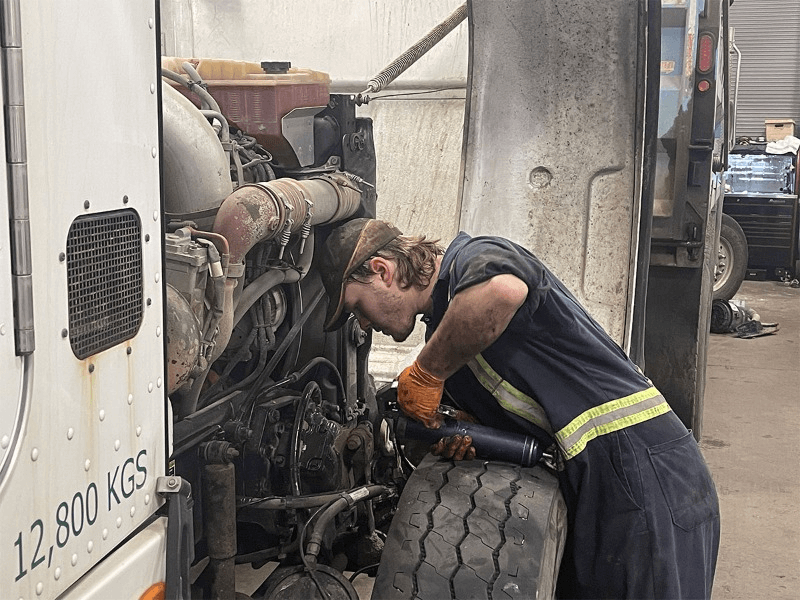

Staffed by knowledgeable technicians and equipped with the latest diagnostic tools, we guarantee every repair is completed quickly and correctly the first time. We understand that time is money, and our priority is to reduce your downtime and send you back on the road with peace of mind.

In the sections below, we’ll take a closer look at the primary services, benefits, and advice on selecting the best truck repair shop.

Key Takeaways

- Selecting the best truck repair shop ensures optimal performance when you need it. It increases safety and lowers the long-term costs associated with substandard repairs.

- Check for certifications, training, and adherence to industry standards to ensure the shop is committed to safety and quality, just like we expect from our cars.

- Compare the shop’s history with your truck’s make, model and specialized systems.

- Focus on customer service, open communication, and honest turnaround times to keep customers happy and bikes rolling.

- Regular preventative maintenance combined with customized maintenance plans will keep your truck in operation longer, increase uptime, and help your entire fleet run more efficiently.

- Confirm the shop’s good standing via referrals, quality award nominations, and before-and-after case studies to ensure their reliability and commitment to quality.

Why Choosing the Right Shop Matters

Choosing the right truck repair shop can make all the difference for your vehicle performance. It would be an investment in your safety while sharing the road. Regular maintenance from a quality shop is key to getting the best performance out of your diesel engine and that means better fuel economy and performance.

Less downtime with all the services you need under one roof, you’ll lower downtime and keep your operation going strong. Only shops that use the highest quality, genuine OEM parts avoid premature failures, which is usually a result of cheap imitations. Prioritization on high-quality parts is extremely important, given that the quality of the part is a cause in nearly 80% of breakdowns.

Safety is a big one as well. Trucks are designed to carry extremely heavy loads over long distances, so the repairing of body components must be done highly accurately. Experienced mechanics with specialized training can spot potential issues before they become hazards, reducing risks for drivers and others sharing the road.

A quality shop focuses on quality inspections, making sure your truck is safe to operate after each service. Financially, if you go with a repair shop that you know and trust, you will save money in the long run. Although Denver Tire and Auto Repair, it’s tempting to take shortcuts, shoddy repairs or inferior parts usually just make for a more expensive re-breakdown.

Certified specialists bring years of valuable field experience. They know how challenging diesel engines are, and with excellent maintenance knowledge, they can prolong your truck’s life by years. Their decades of real-world experience has them primed to tackle complex repairs quickly, preventing expensive downtime.

As always, great repairs prevent the truck from further compromising. A shop with a proven track record and certified mechanics ensures dependable service, keeping your truck roadworthy and your business on track.

What Defines a Good Truck Repair Shop?

Understood on your own, these simple yet vital considerations will help you identify the premier truck repair shops from the average ones. These attributes guarantee superior service and valuable peace of mind for truck owners and fleet managers.

1. Check for Relevant Certifications

Certifications are a direct indicator of professionalism and expertise. A shop must be certified in truck-repair specific certifications, whether that’s from the actual manufacturers or organizations within the industry.

Well-trained technicians with a commitment to continuing education prove they are capable of performing specialized work such as emission system repairs or CVIP inspections. Familiarity with safety and industry best practices is key.

It demonstrates the shop’s commitment to providing superior service and maintaining integrity in their operations.

2. Evaluate Repair Experience and Expertise

In truck repair, experience does count. A good history of servicing different makes and models goes a long way.

Truck and repair shops that employ a minimum of 10 experienced mechanics — with specialist mechanics for complex repairs — are more capable of handling heavy-duty vehicles.

Ask for references from previous successful repairs, such as engine problems or retrofitted air conditioners to understand their track record.

3. Assess Customer Service and Communication

Great customer service goes a long way in building trust. Shops with responsive staff and proactive communication regarding repair expectations and costs will rise to the top of your options.

Positive reviews on Google (4.5 stars or higher) and BBB accreditation are signs of a safe and trustworthy shop. Facilities that update you every step of the way prove they’re putting their customers first.

4. Understand Turnaround Time Realistically

Timely repairs have a direct effect on fleet productivity and effectiveness. An excellent shop understands the need for both efficiency and thoroughness, providing flexible scheduling for preventative maintenance and quick response time for emergencies.

This provides peace of mind with minimal downtime and operational disruptions.

Common Truck Repair Services Explained

To ensure your truck stays in the best possible shape, you should be paying close attention to each of its many systems regularly. Your dependable commercial truck repair shop should provide a comprehensive suite of critical repair and maintenance services to keep your fleet running smoothly and safely at all times.

Examples of these are engine diagnostics, brake inspections, transmission repairs, suspension maintenance, electrical troubleshooting, and exhaust system servicing. Each one is vitally important to keeping your truck safe, reliable, and holding its value.

Engine Diagnostics and Overhauls

Diagnostics are usually the first line of defense in diagnosing performance issues. Modern technology allows mechanics to better diagnose issues, saving time and eliminating guesswork.

Overhauls, which include the replacement of all worn or ineffective components, return aging engines to prime operating condition. Taking care of small engine problems right away stops expensive breakdowns and lost time from happening.

The best good repair shop with the experience and knowledge to take on a variety of engine configurations will know the fix is right.

Brake System Inspections and Repairs

The brake system works hand-in-hand with safety. Safety inspections include pads and rotors as well as fluid levels.

Problems such as worn pads or leaky hoses can affect the ability to stop safely. When repairs are made promptly, brake repairs help avoid potential accidents and they increase the lifespan of brake components.

Brake systems unique to commercial trucks require expertise to ensure safe, dependable service.

Transmission and Clutch Services

Transmission and clutch system performance is vital to trucking operation. Indications like slipping gears or trouble shifting let you know that it’s time to get service.

Simple procedures such as regular fluid changes make all the difference in lifespan. Whether it’s an automatic, CVT, or another type, a qualified repair shop will keep your truck running well under the hood.

Suspension and Steering Repairs

Steering and suspension systems are key to body control and ride comfort. Tire issues such as pulling or uneven wear suggest alignment issues.

Routine inspections every 19,000 kilometers are crucial to ensure that issues are identified and addressed right away. Whether structural or cosmetic, mending these systems makes the ride better and safer.

Electrical System Troubleshooting

With today’s trucks equipped with sophisticated electrical systems, their repair requires a special focus. Whether it be replacing a bad light or diagnosing a troublesome sensor, accurate diagnostics are key to fixing the issue right away.

Experienced and skilled technicians guarantee accurate repair while saving systems energy and money.

Exhaust and Emission System Services

Regular exhaust system maintenance is essential to ensure your vehicle is running as efficiently and cleanly as possible. Common problems are leaks or blockages that affect airflow and performance.

Shops that are experienced at doing the right repairs maximize their shops’ efficiency while following all legal regulations.

Risks of Selecting the Wrong Shop

Choosing the right truck repair shop is more than a convenience. It’s a necessity to ensure safety, save money, and maintain performance. One bad choice can start a domino effect of issues that hurt both your car and wallet.

Unnecessary Repairs and Part Replacements

Worse yet, some shops will recommend unnecessary repairs or replacements to line their own pockets instead of being up front. An easy brake adjustment, for instance, can be padded into a full brake replacement. This is where getting a second opinion before agreeing to any major repair work can be worth its weight in gold.

Without it, you run the chance of bleeding your budget dry on avoidable repairs. Transparency is key to this process. A well-respected shop will walk you through the repair process and explain why a service is needed in a way that prevents unnecessary spending.

Always ask for a line item breakdown of the costs to determine how truthful they may be.

Potential Safety Hazards and Liabilities

Poorly executed repairs can compromise road safety, such as a misaligned axle that leads to uneven tire wear or failed braking systems. These problems don’t only endanger drivers; they expose cities to legal liability.

A well-known shop’s safety history is an indicator of quality. Partnering with a well-established, well-respected repair partner reduces these risks and keeps your truck safe.

Increased Downtime and Lost Revenue

Long repair timelines can be an operational killer, particularly for those businesses that operate with a specific fleet availability. For them, downtime translates to lost revenue, making their need for speedy processes all the more urgent.

While the best partner shops still prioritize quality work, those that offer extended hours or 24/7 service limit downtime and ensure your truck stays on the road.

Higher Long-Term Repair Costs

When you cut corners using the cheapest repairs, you’re just setting yourself up for a series of breakdowns and expenses. High-quality repairs, which include warranties, are more cost-effective in the long run.

Investing in a reputable shop ensures proper maintenance and avoids escalating expenses.

Fleet Maintenance: Key Considerations

Thoughtful vehicle maintenance is a key to keeping vehicles reliable, safe and cost-effective. By considering holistic influences and making use of predictive management techniques, you have the potential to greatly improve fleet efficiency and save money.

Custom Service Reporting

Customized maintenance reports provide a clear overview of each vehicle’s service history, helping you make informed decisions about repairs and replacements. Beyond that, these reports make budgeting easier by pointing out problems sources you need to repeatedly fix and predict costs ahead.

For instance, monitoring driver vehicle inspection records (DVIRs) goes a step further, helping you stay compliant and identify issues before they become critical. In-depth reporting can easily identify trends like common part failures, allowing you to improve processes for quicker repairs and reduced downtime.

Your shop should provide full-service reporting, featuring odometer-based reminders delivered directly to your inbox.

Tailored Maintenance Plans

Of course, no trucks wear the same. Which is why developing maintenance plans based on a vehicle’s specific duty cycles is crucial. What about trucks with high mileage or heavy loads?

Custom-fit schedules give fleets the flexibility to match operational needs, so maintenance intervals take into consideration the stressors of everyday use. For example, automating our maintenance processes or having mobile columns that lift multiple vehicles a day upstairs pocket hours of technicians’ time.

Focused, customized, and strategic plans drive efficiency, reduce overall costs, and ensure the highest level of asset reliability is achieved.

Emergency Repair Protocols

Emergency repairs require immediate response to avoid extended out of service time. Rapid response times, clear lines of communication, and having procedures clearly articulated and understood go a long way.

Shops prepared for urgent requests, with organized tools and parts at hand, reduce revenue loss—$1.50 per minute on average—when technicians wait for parts. Being prepared is the best way to ensure that your operations experience the least possible disruption.

Minimizing Fleet Downtime

Proactive maintenance, such as preemptive inspections and choosing the right lift for each task, avoids breakdowns and disaster to ensure fleets are always operational.

Only the efficient shops, who work daily to maximize turnaround speed, are saving those shops hours during preventive maintenance and repairs. Increased uptime keeps your operations productive, which of course improves your bottom line.

Beyond Repairs: Value-Added Services

Today, truck repair shops are shifting to become centers for value-added services that go beyond truck maintenance. Value-added services can differentiate a business in the competitive repair space, improve customer satisfaction and ensure long-term fleet health.

These value-added services streamline processes and increase client retention. This is what makes them indispensable for any repair shop.

Performance Tuning and Modifications

Ensuring fuels and engines are performance tuned to achieve the best fuel efficiency with the right engine power is key to tackling operating costs. Upgrades in equipment like suspension systems, turbochargers or braking systems will help address the wear and tear on safety as well as operations.

Skilled technicians ensure these upgrades meet the unique needs of each truck, delivering reliable results. A shop with a track record of successful performance improvements can increase confidence, particularly for customers looking for more tailored, cutting-edge solutions.

Heavy Equipment and Hydraulic Services

Whether it’s lifting a dump bed, controlling steering or braking, hydraulic systems power key functions in heavy-duty trucks. Goods worth thousands of dollars can be repaired, such as cylinder replacements or valve adjustments, and preventive maintenance like oil and fluid checks completely avert an expensive breakdown.

Shops with the right technology and a skilled workforce are more effective at cutting down on the kind of heavy equipment downtime that affects bottom lines. Giving hydraulic systems the proper care increases equipment lifespan, saving fleet operators money.

Telematics Integration and Support

Telematics simplifies fleet management by allowing real-time data to power your decisions. Through the use of GPS tracking and fleet-wide diagnostics, repair shops enable fleets to operate more efficiently and cut down on fuel waste.

Ongoing support ensures systems function flawlessly, and experienced providers can customize solutions for diverse needs, enhancing overall fleet performance.

Driver Training Programs

Driver training through eco-driving techniques not only reduces accidents, but increases fuel efficiency. Production and implementation of these comprehensive programs that focus on safety helps drivers control the vehicle and can avoid the crash.

Since well-trained drivers are a key component of fleet reliability, this service is an absolute necessity.

Extending Truck Lifespan: Expert Tips

Caring for a truck goes beyond knowledge of daily inspections. It involves a strategy of preventive maintenance and repair. By prioritizing preventive maintenance and nipping problems in the bud, you will safeguard your investment and minimize costly unplanned downtime.

Here are practical steps to keep your truck running smoothly for years:

Cost-Effective Preventative Measures

Preventative maintenance is an inexpensive investment that helps you avoid big-ticket repairs down the road. Maintaining tire pressure by checking it on a weekly basis and rotating tires every 5,000 to 7,000 miles can help tires last longer.

The best way to protect the engine is by using EPA-registered additives approved by manufacturers. In addition, premium-grade diesel fuel with the appropriate cetane levels ensures the best ignition properties.

Shops with 40+ years of skills and experience will tell you these tried-and-true approaches are the best way to boost reliability and save money.

Regular Inspections and Maintenance

That’s why routine inspections are so important — catching issues before they become bigger problems. Plan on detailed inspections of brakes, electrical systems and engine components.

This helps you stay compliant with DOT safety regulations and reduces the chances of breaking down. To provide one example, newer trucks with intricate electrical systems do well with consistent evaluations to avoid sudden failure on the road.

A trusted repair shop emphasizes thorough inspections to maintain safety and performance.

Addressing Minor Issues Promptly

Putting off small issues can spiral into big ticket repairs. By addressing problems early, such as a small leak or a strange noise, you can avert bigger damage down the line.

For instance, fixing a small coolant leak will prevent an overheating radiator and engine seizure. Proactive shops value responsiveness and consider doing timely repairs as part of proactive maintenance and overall vehicle health.

How to Evaluate Shop Reputation

When you select the right truck repair shop, their reputation may be one of the most important factors to consider. A shop’s reputation speaks to its trustworthiness, customer service, and quality of work. Thinking through this aspect goes a long way in helping your truck receive the attention it deserves without costing you time and money.

Seek Referrals and Recommendations

Referrals from trusted sources, such as other truck owners or fleet managers, are invaluable. These folks usually have great insight into common experiences with repair shops and can help point you to trustworthy shops.

Word-of-mouth recommendations from fellow industry professionals or friends are powerful because they reflect real-life experiences. For instance, if a fleet manager consistently praises a shop for timely repairs and transparent pricing, it’s a strong indicator of trustworthiness.

Referrals prevent you from going to shops with patterns of problems, so you’d be more likely to go to shops that value customer happiness.

Read Online Reviews and Testimonials

From craftsmanship to customer service, online reviews can be an excellent resource for evaluating a shop’s reputation. Online review platforms such as Google and Yelp can help you uncover other shopping performance trends.

Positive reviews will usually showcase great service, and negative reviews can indicate potential issues. When reading reviews, look for trends and not one-off issues.

A BBB-accredited shop with certifications such as ASE or Red Seal usually rises to the top, indicating competent technicians and a high level of accountability. Just be wary of the outliers on either end, since they usually don’t tell you the full story about a shop’s reputation.

Case Studies Highlighting Repair Quality

Fellowship case studies are a good hands-on indicator of a particular shop’s practices and expertise. Typical high-fives repaired engines, and strange exotic imports that wandered in from across the country — testimony to their talents and expertise.

Clear expectations—such as a thorough walkthrough of needed repairs and what they will cost—foster a sense of trust. Shops providing these details are showing they have a customer-first approach and focus on quality workmanship.

Conclusion

Choosing the right truck repair shop is everything. With a longer-lasting truck, less downtime and money saved, it pays for itself. The best shops provide knowledgeable technicians, trustworthy service, and honest communication. Preventing problems It’s all well and good to say, we’ll fix your truck before something breaks and you’re stuck on the side of the highway.

Don’t rush the process—make sure you read reviews, ask questions and price shop services. With a trusted independent shop looking after your truck’s best interests, you’ll hit the road to minimize downtime and maximize your bottom line. When the need arises—be it basic maintenance or extensive truck collision repair services—partnering with experienced, knowledgeable professionals will guarantee a better experience with less hassle.

Your truck deserves nothing but the finest care. Don’t accept mediocre. Even if you feel like you have to, find a shop that prioritizes quality workmanship and trust. Your customers are counting on you. Your business relies on it.

Frequently Asked Questions

Why is it important to choose the right truck repair shop?

Choosing the right shop means getting quality repairs that make you safe and save you money in the long-run. Qualified technicians with the right tools mean you won’t have to repeat problems, and your truck will be on the road longer.

What are the signs of a reputable truck repair shop?

Check their certifications, customer reviews, and pricing transparency. The ideal shop is one that’s upfront with communication, warranties their work, and employs ASE-certified technicians specializing in heavy-duty truck repairs.

What services are commonly offered by truck repair shops?

Most auto repair shops can handle engine work, brake service, new tires, transmission repair and electrical system diagnostics. Many provide preventative maintenance and fleet services as well.

How can poor repair services affect my truck?

Poor quality maintenance turns into busts, repairs that are more expensive, and jeopardizes safety. What’s more, picking the wrong repair shop can void warranties or lead to using substandard parts.

Can a repair shop help extend my truck’s lifespan?

Yes, regular maintenance, timely repairs, and expert tips from technicians can significantly extend your truck’s lifespan, ensuring optimal performance and reliability.

What should I check before trusting a repair shop?

Look at their certifications, their reviews online, and if they have experience working on different types of trucks. Inquire as to what types of warranties they offer, what quality of parts they use, and that they offer services geared towards fleets.

Are value-added services worth considering?

Right on the money there. Offer value-added services greater convenience and greater accuracy includes services such as roadside assistance, maintenance plans, and fleet diagnostics. They increase safety, save the American public time and money, and improve overall truck performance.

CHECK OUT OTHER SERVICES OFFERED AT GET ‘R DONE:

Commercial Vehicle Inspections (CVIP)