Did you know that nearly 20% of commercial trucks experience a breakdown every year? This can lead to costly delays and lost revenue. Understanding the common causes of commercial truck breakdowns is essential for fleet managers and drivers alike. Regular maintenance and quick troubleshooting can save time and money. Knowing how to handle these situations ensures smoother operations.

In this post, we’ll dive into the top reasons why commercial trucks break down and share tips on prevention and recovery. Whether you’re a seasoned driver or new to the industry, this guide will equip you with valuable insights. Stay ahead of potential issues and keep your fleet running efficiently.

Key Takeaways

- Regularly inspect your truck for common breakdowns like engine issues, exhaust problems, and battery failures to catch problems early.

- Pay attention to warning signs from your vehicle, such as unusual noises or dashboard alerts, which can indicate mechanical issues.

- Implement a routine maintenance schedule that includes checking fluid levels, tire condition, and battery health to prevent breakdowns.

- Educate yourself on basic troubleshooting steps for common issues so you can address minor problems before they escalate.

- Consider using professional services like ‘Get ‘R Done Services’ for timely repairs and maintenance that can save you time and money in the long run.

- Stay informed about industry best practices and safety tips to ensure your commercial truck remains in optimal working condition.

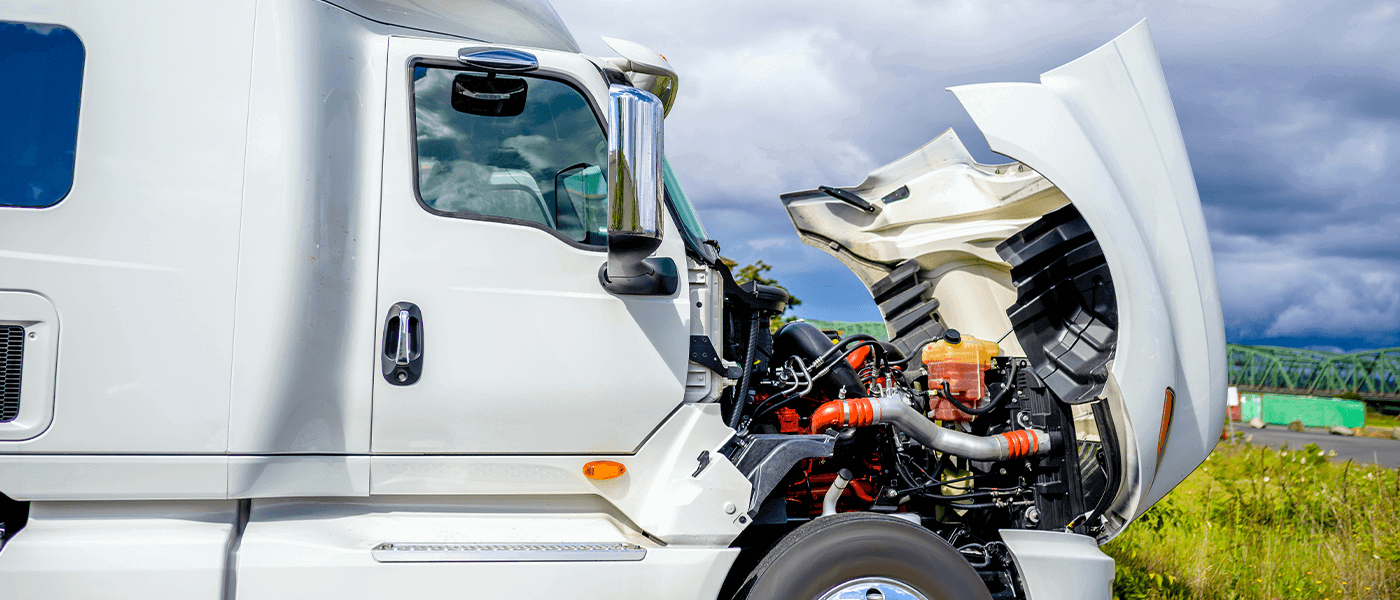

Common Truck Breakdowns

Tire Blowouts

Tire blowouts are a frequent issue for trucks. Regularly inspect tires for signs of wear and damage. Look for cracks, bulges, or uneven tread. Maintaining proper tire pressure is essential to prevent blowouts. Under-inflated tires can heat up and fail. Replace worn tires promptly to ensure safety on the road. A blown tire can lead to serious accidents.

Brake Failures

Brake failures can be life-threatening. Schedule routine brake inspections to catch issues early. Mechanics can identify worn pads or damaged rotors during these checks. Monitor brake fluid levels and replace as needed. Low fluid can lead to brake failure. Address unusual noises or sensations when braking immediately. Ignoring these signs increases the risk of accidents.

Oil Leaks

Oil leaks are another common problem in commercial trucks. Check for oil spots under the vehicle as a sign of leaks. These spots indicate that oil is escaping from the engine. Regularly inspect seals and gaskets for wear. Damaged seals often cause leaks. Using high-quality oil helps minimize the risk of leaks. Quality oil maintains engine health and performance.

Electrical Problems

Electrical problems can disrupt truck operations significantly. Test the battery and alternator regularly for optimal performance. A weak battery may leave you stranded on the road. Inspect wiring for frays or corrosion that could cause failures. Damaged wires can lead to short circuits and other issues. Utilize diagnostic tools to identify electrical issues quickly. Early detection prevents larger problems down the line.

Engine and Mechanical Issues

Overheating Engines

Engine overheating is a common issue for commercial trucks. Drivers must monitor coolant levels regularly. Topping off coolant can prevent overheating. Inspecting hoses and connections is crucial too. Look for leaks or damage that could lead to coolant loss. Keeping an eye on temperature gauges during operation helps catch problems early.

Engine Malfunctions

Engine malfunctions can cause serious delays. Listening for unusual sounds is important. These sounds may indicate engine trouble. Drivers should check for warning lights on the dashboard and respond promptly. Ignoring these lights can worsen the problem. Regular oil changes maintain engine health. This simple step can extend the engine’s lifespan significantly.

Clutch Breakdowns

Clutch breakdowns disrupt operations. To prolong its lifespan, avoid riding the clutch. This habit can wear it out faster than normal use. Recognizing signs of clutch wear is key. Drivers should look for slipping or difficulty shifting gears. Scheduling clutch inspections as part of regular maintenance prevents major issues down the line.

Suspension Failures

Suspension failures affect handling and safety. Pay attention to any changes in how the truck handles. Uneven tire wear can also signal suspension issues. Inspecting suspension components during maintenance is essential. Look for damage or excessive wear that could compromise performance. A test drive can reveal unusual noises or vibrations that need addressing.

Exhaust and Battery Concerns

Exhaust System Issues

Loud noises can signal exhaust leaks. Drivers should listen closely for these sounds. They often indicate a problem that needs immediate attention. A leak can lead to reduced engine performance and increased emissions.

Inspecting exhaust hangers and pipes is essential. Rust or damage can weaken the system. These issues might cause parts to break or fall off while driving. Regular checks help catch problems early.

Emissions systems must function correctly. Failing to do so can result in fines from regulatory agencies. Drivers should ensure that their vehicles meet local emissions standards. This avoids costly penalties and maintains compliance with environmental laws.

Battery Failures

Battery terminals require regular checks for corrosion. Corrosion can prevent the battery from delivering power effectively. Cleaning terminals can improve performance significantly. Use a mixture of baking soda and water to clean corroded areas.

Monitoring battery age is crucial. Most truck batteries last about three to five years. Replacing a battery nearing the end of its lifespan prevents unexpected breakdowns. A dead battery can leave drivers stranded, causing delays and frustration.

Testing battery performance regularly is important, especially in extreme weather conditions. Cold temperatures can reduce battery efficiency significantly. Drivers should perform tests during winter months to ensure reliability. Hot weather also affects battery life, so checks are necessary year-round.

Prevention Tips

Regular Maintenance Importance

Regular maintenance is crucial for commercial trucks. Schedule service appointments consistently. This helps keep vehicles in top shape and reduces breakdown risks. Documenting the maintenance history is also essential. It allows tracking of repairs and replacements over time. Educating drivers about the importance of reporting issues promptly can save money and time. Drivers should feel empowered to communicate any concerns they notice.

Early Problem Detection

Implementing a pre-trip inspection checklist is vital. This checklist helps drivers identify potential problems before hitting the road. Encourage drivers to report any unusual vehicle behavior immediately. Early detection can prevent minor issues from becoming major breakdowns. Using telematics technology enhances monitoring capabilities. Real-time data on vehicle performance allows for quick responses to any signs of trouble.

Keeping Brakes Healthy

Brakes are one of the most critical components of a truck. Replacing brake pads and rotors according to manufacturer recommendations is necessary for safety. Cleaning brake components regularly prevents dust buildup and overheating, which can lead to failures. Educating drivers on safe braking techniques also extends brake life. Proper use of brakes reduces wear and tear, ensuring better performance over time.

Get ‘R Done Services

Comprehensive Repair Solutions

Commercial trucks face many challenges on the road. Repair services must cover a wide range of issues. These services include engine repairs, brake replacements, and electrical system checks. Providing transparent estimates is crucial. Customers need to know the costs upfront. Timelines for repairs should also be clear. This helps businesses plan their deliveries without unnecessary delays. Technicians must receive training in the latest repair technologies. This ensures they can handle modern truck systems effectively.

Expert Technicians

Hiring certified technicians is essential for quality work. Experience in commercial truck repairs makes a difference. Skilled technicians can quickly diagnose problems and suggest solutions. Ongoing training keeps staff updated on industry standards. This investment pays off in better service and fewer mistakes. A culture of safety and quality should be promoted in all repair work. Employees must understand the importance of these values. This leads to higher customer satisfaction and trust.

Rapid Response Assistance

Breakdowns can happen at any time. Establishing a 24/7 roadside assistance program is vital for support. This program ensures help is always available when needed. Service vehicles must be equipped with essential tools and parts for quick repairs. Technicians should be trained to handle emergencies efficiently and effectively. Fast response times minimize downtime for trucks and drivers. This approach helps companies maintain their schedules and meet delivery timelines.

Summary

Breakdowns can hit you hard, but knowing the common issues keeps you ahead. Engine problems, exhaust troubles, and battery failures are the usual suspects. Prevention tips help you dodge these headaches, while services like Get ‘R Done ensure you’re back on the road fast.

Stay sharp and proactive. Regular maintenance is your best friend. Don’t wait for a breakdown to take action. Invest in your truck’s health now. You’ll save time and money in the long run. Check out reliable services and keep your fleet running smoothly. Your peace of mind matters. Take charge today—your truck deserves it!

Frequently Asked Questions

What are the most common causes of commercial truck breakdowns?

Common causes include engine failures, mechanical issues, battery problems, and exhaust system failures. Regular maintenance helps prevent these breakdowns.

How can I identify engine issues in my truck?

Look for warning lights on the dashboard, unusual noises, or decreased performance. Regular diagnostics can help catch problems early.

What should I do if my truck breaks down on the road?

Stay calm and pull over to a safe location. Use hazard lights, call for roadside assistance, and avoid attempting repairs yourself if you’re not trained.

How can I prevent truck breakdowns?

Regular maintenance checks, timely oil changes, and monitoring tire health can significantly reduce the risk of breakdowns.

Are there specific battery concerns for commercial trucks?

Yes, watch for corrosion, loose connections, and signs of wear. Regularly testing your battery can prevent unexpected failures.

What are some common exhaust system issues?

Common issues include leaks, rust, and blockages. These can affect performance and emissions; regular inspections are crucial.

How can Get ‘R Done Services help with truck breakdowns?

Get ‘R Done Services provides prompt roadside assistance, expert diagnostics, and reliable repairs to minimize downtime and keep your truck running smoothly.

CHECK OUT OTHER SERVICES OFFERED AT GET ‘R DONE:

Commercial Vehicle Inspections (CVIP)

Mobile Service Truck

Fleet Maintenance and Repair

BROKEN DOWN NEAR EDMONTON, AB?

HERE ARE GET ‘ R DONE’S TOP RESOURCES:

Edmonton Travel Hotels

Edmonton Things to Do

Edmonton Places to Eat

Edmonton Weather